[Feature] Prof. Park Min-sik Opens a New Era in Electric Vehicles

The research team led by Prof. Park Min-sik, from the Dept. of Advanced Materials Engineering at Kyung Hee University (KHU), and Prof. Lee Jong-won, a professor in the Division of Materials Science and Engineering at Hanyang University, has developed a fast-charging battery technology, which was announced on March 7, 2025. This research was recognized for its achievement and published in Advanced Materials in February, with the title Toward Fast-Charging and Dendrite Free Li Growth on Natural Graphite Through Interfacial/Concentration/Constriction Controlled MoS₂ Nanosheets. Prof. Park’s research team has opened new possibilities for reducing consumer’s hesitation toward Electric Vehicles (EV) by innovatively reducing charging time.

The Limitations of the Current Battery

Prof. Park said, “Uneven lithium plating on natural graphite (NG), a conventional material for batteries, is the obstacle to the fast-charging and stability of the batteries.” NG has issues with lithium plating under fast-charging conditions. Lithium plating refers to the uneven deposition of lithium in solid form on the surface of the NG, which causes a decrease in the battery’s stability. In severe cases of lithium plating, it physically connects the cathode and anode, which are the two opposite electrodes in a battery. This can cause the battery’s lifespan to shorten or trigger a short circuit. The short circuit causes the rapid movement of lithium ions and an increases in thermal energy. As a result, it increases the likelihood of a battery explosion. To prevent this, metallic coating technologies have been used.

However, previous research using titanium dioxide, aluminum oxide, and molybdenum oxide has caused unpredictable solid electrolyte interphase (SEI) formation. The SEI is a thin layer that forms between the anode and the electrolyte, which fills batteries. The formation of SEI can have a critical impact on batteries. If it is formed controllably and uniformly, SEI doesn’t disturb the electrochemical properties and stability of the anode material. Though, if it is formed unevenly or unstably, it can lower the performance and stability of the battery. In previous research, many materials formed an unstable SEI that could not satisfy complex functional requirements. Prof. Park’s research team demonstrated that by using molybdenum disulfide (MoS₂) as the coating material, maintaining battery performance without any energy density loss.

Fast-charging Without Energy Density Loss

Prof. Park mentioned, “The key is shortening charging time without compromising energy density.” Previous methods of reducing the charging time relied on a trade-off approach that decrease the battery capacity. Yet, this causes discomfort for the EV users, and high energy capacity is often associated with long charging time. This research demonstrates the possibility of shortening charging time and maintaining energy capacity.

Furthermore, this research solved the battery performance and stability issues. Molybdenum disulfide, with the chemical formula MoS₂, is commonly used as a lubricant for mechanical components to move smoothly. However, this material has limitations in its bulk form, as it disturbs the movement of lithium ions and increases battery weight. Prof. Park’s research team applied MoS₂ in a thin-coating method, which can maintain lithium ions’ movement and battery stability.

Prof. Park mentioned that the coating process of MoS₂ was the most challenging part of the research. They tried many times to coat MoS₂ on NG evenly, but initial attempts failed. At this point, Lee Jun-won, one of the members of his team, solved this problem by adding a thermal process.

Prof. Park’s NG coated with MoS₂ forms a more even SEI, making the battery more stable. Due to its low absorption of energy, MoS₂ can attract lithium ions easily with lower energy requirements. Attracted lithium ions are easily stored between the layers of coating material and have higher stability. Lithium ions stored between coating layers become another phase of chemical materials, and they store the electrons in this process, which is called ‘charging process’. Afterward, the material emits the stored electrons by discharging. MoS₂ plays a key role in attraction, storage, and transfer of lithium ions.

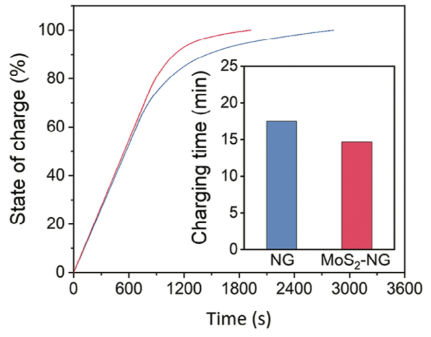

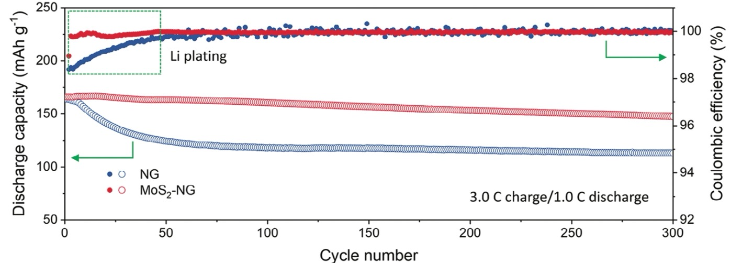

Anode materials coated with MoS₂ showed excellent performance under fast-charging conditions and demonstrated strong battery durability. According to the paper, a battery coated with MoS₂ takes 14.7 minutes for 80% charging. It demonstrated a 16% reduction in charging time compared to conventional NG material. Moreover, during the 300 cycles of charge-discharge of the battery, it maintained its original battery performance.

Comparison of charging performance between NG and MoS₂-NG anodes

photo: Advanced Materials (advanced.onlinelibrary.wiley.com)

Comparison of cycling performance between NG and MoS₂-NG anodes

photo: Advanced Materials (advanced.onlinelibrary.wiley.com)

Safety Issues That Simultaneously Overcome

Prof. Park said, “It seems that the battery coated with MoS₂ will demonstrate excellent safety performance for EV users.” He added, “Lithium plating and thermal issues are mostly caused by environmental conditions, but the fact that we solved the lithium plating issues means we can expect improved battery safety.”

This research improved the performance of lithium-ion batteries and got rid of the obstacle for users who feel discomfort with EVs. Prof. Park said, “As a lot of battery companies contacted me, the EV industry has shown strong interest in fast-charging technology.” Furthermore, he mentioned, “But the technology used in this research is not yet industrialized. Therefore, we are planning to conduct further research using alternative methods such as atomic layer deposition, in collaboration with Prof. Jeon Woo-jin, from the Dept. of Advanced Materials Engineering at KHU.”

Prof. Park’s research team demonstrated the excellence of fast-charging technology and the performance of the battery by using the MoS₂ coating method. Prof. Park said, “We will conduct further research comparing other materials that satisfy similar conditions.” As this research solved not only the discomfort of consumers but also the safety problems, it is expected to open new possibilities for innovative growth in the EV industry.

There are no registered comments.

I agree to the collection of personal information. [view]